The current economic climate impacts every single bakery business regardless of size. We must all work closely together, find ways to navigate cost increases and think differently.

In the past years, there has been a general trend of increasing prices for many raw materials. The challenges just seem to continue with disruption in the supply chain, costly logistics and expensive power consumption. Inflation is impacting the entire road from the raw materials to the end products, in some cases increasing total cost per product up to double.

– Many of our customers focus more than ever on being as efficient as possible, says Reto Dietiker, Export Business Development Manager at Bakels Sweden. We help in replacing ingredients and adjusting recipes to lower cost, but also avoid food waste and optimize production and logistic.

Let us look into three solutions,

that can create better conditions to meet these challenges.

1. Cake Emulsifier

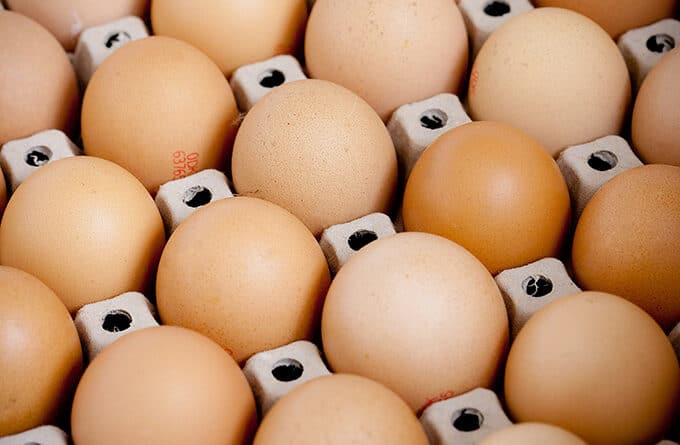

By replacing your whipping agent with a high-performing Cake Emulsifer from Aromatic it is possible to reduce 10–25% of the egg content in the recipe calculated on egg amount. Egg is usually one of the most expensive ingredients in the recipe.

A Middle East-based large-scale producer of cupcakes replaced their local cake emulsifier with Aromatic Jilk 60. The original recipe contained 20% of egg and the egg amount could be reduced by 25%. It lowered the recipe cost but also contributed to a much more stable production process.

You might find this insight helpful: Cake Emulsifiers – a solution when egg prices skyrocket

2. Emulsion

Reduce food waste and optimize production and logistic by adding only a tiny bit of an emulsion. 2–4% of Dorothy or Arosoft Cake improves the freshness and prolongs a soft eating quality for several days or weeks. It provides greater flexibility in the whole supply chain.

3. Shelf-life extenders

A shelf-life extender contributes to less food waste and optimization of production and distribution by adding flexibility and a much wider lifetime window.

Aromatic Shelf-life extenders can preserve cakes packed and stored at ambient temperature for up to one year by inhibiting mould growth and keeping the moisture in the baked cake. No need for refrigeration or freezing means energy and cost savings.

Don’t skip the quality

Don’t make the mistake of trying to save money by cutting quality. Contact us for your unique needs and requirements, and we’ll help you save money while still keeping quality.

Download our industrial cake manufacturing guide and explore the products on our website below.

Psst… Bakels Sweden is the centre of competence in the Bakels Group when it comes to emulsifiers/improvers. Our team consists of competent food engineers and technical experts. Want the tastiest recipes, the latest news and new product notifications? Sign up for our newsletter here then!